In this second article of the "Diagnostics Feature" series, we will be discussing the new liquid temperature measurement.

All our flowmeters are now capable of measuring temperature in addition to flow measurements. Just like flow measurements, the new temperature feature is non-invasive and works by using ultrasound. Customers now have access to both flow and temperature from one unit.

How To Use This New Feature:

Under measurements, Temperature is shown by default anytime you have selected water as the liquid. If you need to change the liquid selection, simply navigate to the liquid setup menu, and use the drop-down to select the fluid you want to use.

Currently, temperature is shown on the diagnostics screen only. We have plans to include the temperature measurement as part of the main measurement view in our Orcas app, so stay tuned for updates. If you are using our Cypress Ultrasonic Flowmeter with the Flow Computer, you may configure the Flow Computer to show the measurement on the screen.

Third, the physics of measuring temperature with ultrasound is coupled with the fluid static pressure. The flowmeter cannot tell the difference. Fortunately, the effect is relatively small for most cases. However, for those of you working at high pressures, it will matter. Whatever the case, you will want to enter the fluid static pressure so the flowmeter can compensate. To do this, simply navigate to the setup menu (press "edit" from the main measurement screen), then select the "advanced" menu button. You will see a field to enter static pressure. Input the number and hit "done". The static pressure you entered will now also show on the Diagnostics screen under "Settings."

Next, take note of the working limitations of the temperature range. The temperature measurement is valid between the range of 32F to 176F (0C - 80C). The range is limited by the nonlinearity of the sound speed in water versus temperature. The meter is unable to distinguish temperatures above 80C from those below it. In fact, as the fluid temperature increases above 80C, the flowmeter will measure a decreasing temperature. Therefore, it should NOT be used outside this temperature range.

Finally, what is the uncertainty of the measurement? We perform what is called an "uncertainly analysis" using the "law of error propagation," (Kline and McClintock, 1953) to understand our products and their capability. This involves a bit of calculus, but the result is very useful to help understand how well we can measure. Results are displayed in Figure 2., at the 65% confidence interval. This is statistical, so read this as "65% of the time the measurement is likely within these limits".

You can see right away that for the smaller diameter pipes, the uncertainty increases - or for larger diameters it decreases. This is because the measurement depends upon time and length. The flowmeter handles the time uncertainty, but the length uncertainties are defined by the pipe tolerances and our ability to measure them.

For example, let's say our ability to know pipe dimensions and set transducer spacing is about +/- 0.03". Compared to a 48" pipe, that is a very small fraction - something like 0.06%. Now consider a small 1/2" diameter, for which the same tolerance is 6%. Big difference! You can see how the pipe tolerances become more critical as the pipe gets smaller.

In summary, the physics says two things: (1) if we are working with small pipes, we should try to do out best to enter the pipe dimensions accurately, and (2) use the largest diameter of pipe you have available to get the best temperature measurement.

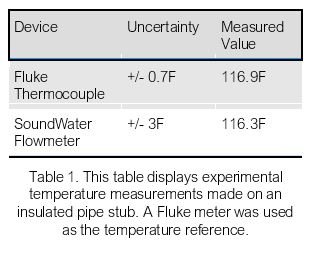

In general, you may look at figure 2 and use it as a guide for what can be expected from a typical setup. Table I shows actual experimental data: we compared SoundWater's measurement to that from a Fluke thermocouple. The results were within a degree of each other.

As always, if you want to know more, or discuss some of these details and products - give us a call.

Happy flow (and temperature) metering!