Ultrasound clamp-on type flowmeters are a convenient tool that allows us to measure flow from outside the pipe, and on a range of pipe diameters and materials. No other technology offers this level of convenience and portability. While it is extremely flexible, and works for most applications, we also need to understand where it works best and where it may not work. This will allow us to use the technology more effectively.

For any clamp-on type ultrasonic flowmeter to produce a measurement, it must be able to transmit ultrasound out of the flowmeter, through the pipe, into the fluid, and back out through the pipe again and return to the flowmeter. If ultrasound is unable to complete this path, then the flowmeter will not have the data it needs to calculate a flow measurement.

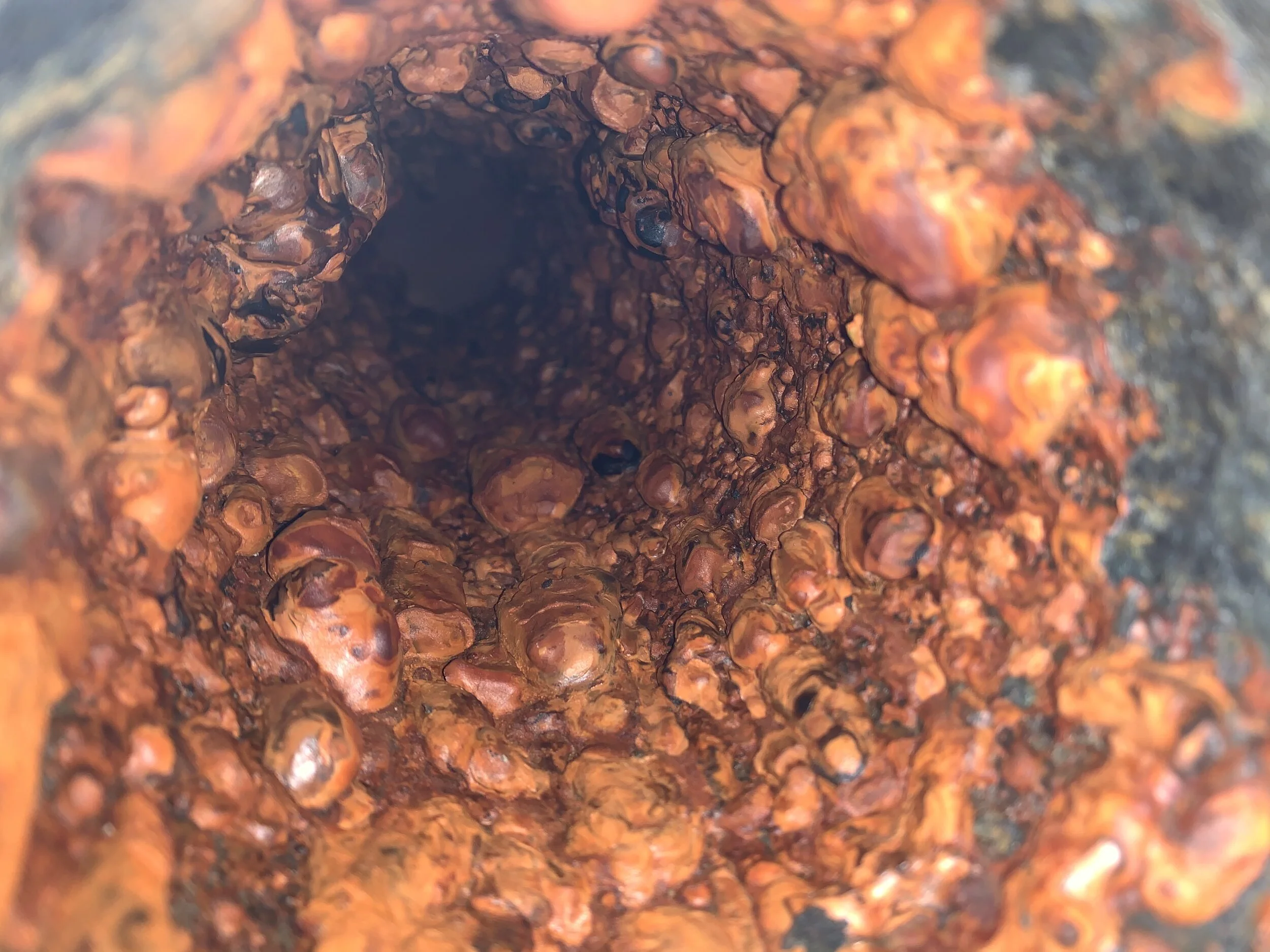

One way this process may fail is if there is corrosion inside the pipe. Corrosion is difficult to identify because we obviously cannot see inside the pipe. It typically occurs on older steel pipes, especially if the fluid inside is corrosive such as chlorinated water. See the image below of a pipe corroded by chlorine.

Ductile iron is commonly found in municipal/utility applications and tends to corrode heavily inside the pipe. In this case, ultrasound will reflect off the corrosion and in the wrong direction, therefore it will not transmit back to the flowmeter. Other materials such as plastic, copper/brass, and stainless steels are less likely to be affected by corrosion.

For pipes that may have corrosion, SoundWater offers solutions to help get an accurate measurement.

First, the flowmeter will apply additional power to the transmitting ultrasound transducer as needed; it can auto-adjust to the changing conditions of the pipe.

Second, the flowmeter can amplify the received ultrasound signal - which it does automatically for you.

Third, the transducers are designed to transmit efficiently, i.e., to have low power loss as the transducer converts electrical energy into mechanical ultrasound energy. Many competitors neglect this, and immediately lose 50% of their ultrasound power which then cannot be used to help penetrate corrosion.

If we know ahead of time that the pipe may be corroded, or especially if it is ductile iron, we offer a special design which removes the reflection at the bottom of the pipe, allowing the ultrasound to pass once through the pipe from one side to the other. When comparing the ultrasound between our two-pass design and our single pass design on corroded ductile iron, we have seen as much as 150x greater amplitude on the single pass design. This bump up in ultrasound signal makes a huge difference in getting a good measurements.

SoundWater Ultrasonic Flowmeters are a great solution if you think you may have corrosion in your pipes. Give us a call and we’ll work with you to find the ultrasonic flowmeter for you.